Understanding Custom Monoclonal Antibody Production Services

Introduction to Custom Monoclonal Antibody Production

Monoclonal antibodies have revolutionized the field of biotechnology and medicine, offering precise targeting mechanisms for a variety of diseases. Custom monoclonal antibody production services play a crucial role in advancing research and therapeutic applications by providing tailored solutions to meet specific scientific needs. This article delves into the significance, processes, and applications of these services, highlighting their impact on modern science and medicine.

The Process of Custom Monoclonal Antibody Production

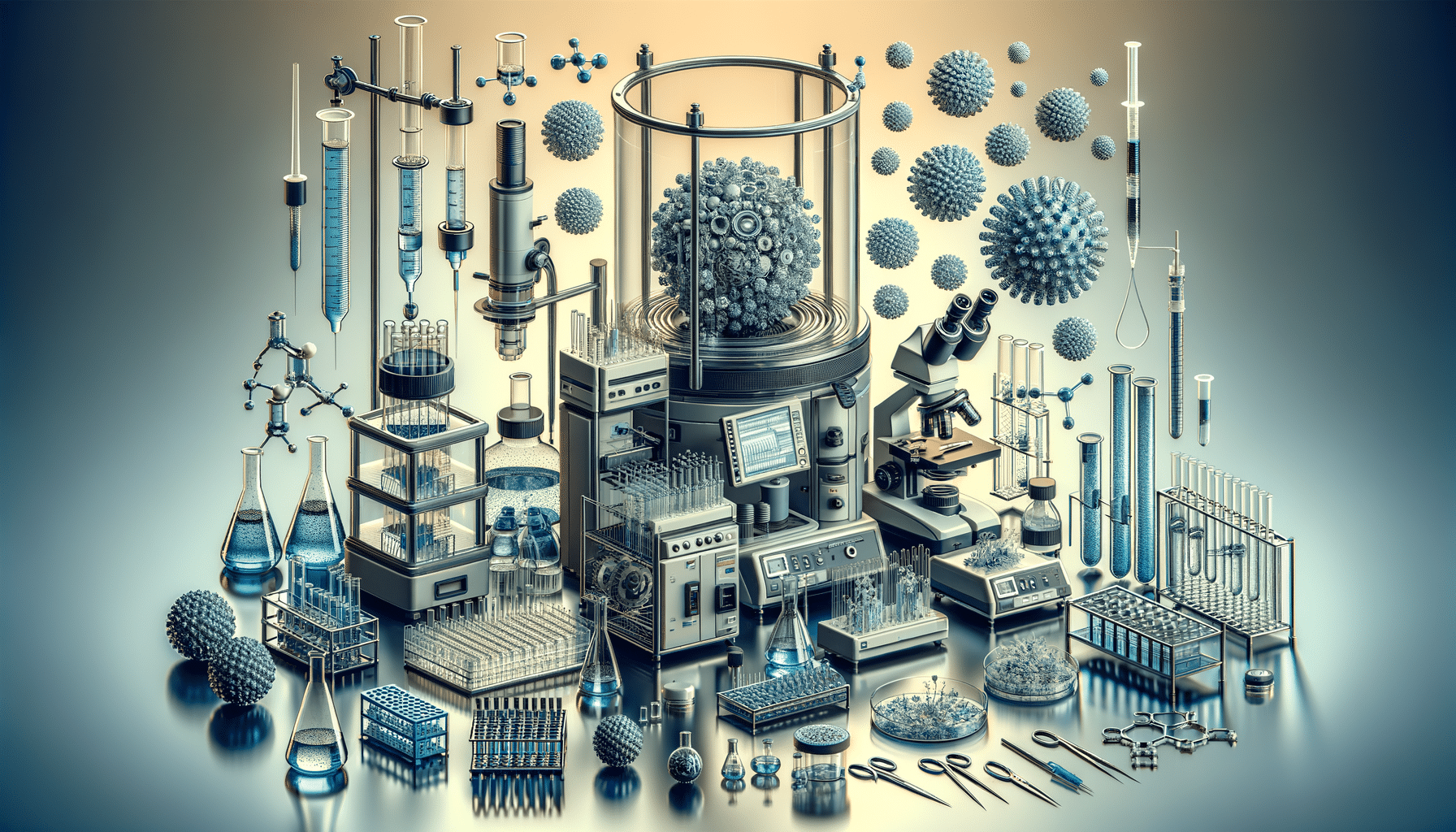

The production of custom monoclonal antibodies involves several meticulous steps, each crucial for ensuring specificity and efficacy. The process typically begins with the immunization of an animal, often a mouse, with the target antigen. This stimulates the animal’s immune system to produce antibodies against the antigen. Following immunization, B-cells are harvested and fused with myeloma cells to create hybridomas, which are screened for the desired antibody production.

Once a suitable hybridoma is identified, it undergoes cloning and expansion to produce large quantities of monoclonal antibodies. These antibodies are then purified and characterized to ensure they meet the required specifications. The entire process requires a high level of expertise and precision, making custom monoclonal antibody production services invaluable for researchers and clinicians seeking specific antibody solutions.

Applications of Custom Monoclonal Antibodies

Custom monoclonal antibodies are indispensable tools in various scientific and medical fields. In research, they are used for detecting and quantifying proteins, studying cellular processes, and developing diagnostic assays. Clinically, monoclonal antibodies are employed in the treatment of diseases such as cancer, autoimmune disorders, and infectious diseases. Their ability to specifically target and neutralize disease-causing agents makes them powerful therapeutic agents.

Moreover, monoclonal antibodies are used in the development of vaccines, offering a pathway to prevent diseases by eliciting a targeted immune response. The versatility of these antibodies underscores their importance in both basic research and applied medical sciences.

Challenges and Considerations in Antibody Production

Despite their widespread use, the production of custom monoclonal antibodies is not without challenges. One of the primary concerns is the time and cost associated with generating specific antibodies. The need for animal models and the complexity of the production process can lead to extended timelines and increased expenses. Additionally, ensuring the stability and activity of the antibodies through storage and handling is paramount to maintaining their efficacy.

Researchers must also consider the ethical implications of using animals in antibody production, prompting a push towards alternative methods such as recombinant antibody technologies. These challenges necessitate careful planning and collaboration with experienced production services to achieve successful outcomes.

The Future of Monoclonal Antibody Production

The future of custom monoclonal antibody production is poised for exciting advancements, driven by technological innovations and increasing demand for personalized medicine. Emerging techniques such as phage display and transgenic animal models offer promising alternatives to traditional methods, potentially reducing the reliance on animal models and expediting the production process.

Furthermore, the integration of artificial intelligence and machine learning in antibody design and screening could streamline the discovery of novel antibodies with enhanced specificity and affinity. As the field continues to evolve, custom monoclonal antibody production services will remain at the forefront of scientific discovery and medical innovation, offering solutions that are both cutting-edge and tailored to individual research needs.