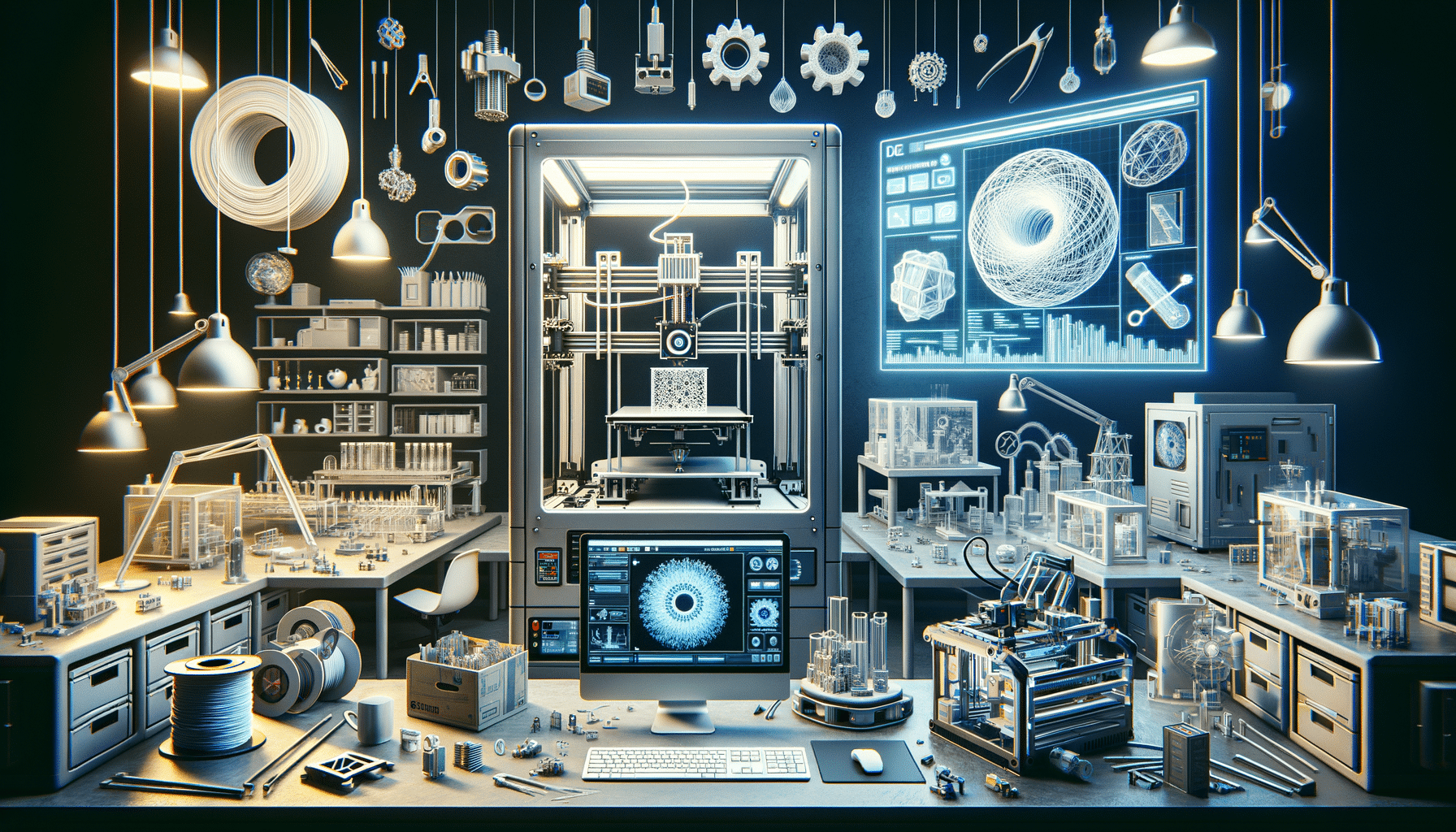

Exploring the World of 3D Printing: Transformative Technology and Its Applications

Introduction to 3D Printing

In recent years, 3D printing has emerged as a transformative technology, reshaping various sectors by offering innovative solutions and unprecedented design flexibility. This additive manufacturing process builds objects layer by layer, using materials such as plastics, metals, and ceramics. The potential of 3D printing is vast, influencing industries ranging from healthcare to aerospace, and even impacting everyday consumer goods. As we delve into the intricacies of 3D printing, we will explore its applications, benefits, and the challenges it faces in becoming a mainstream manufacturing method.

The Mechanics of 3D Printing

Understanding the mechanics of 3D printing is crucial to appreciating its capabilities. The process begins with a digital design, usually created using CAD (Computer-Aided Design) software. This design is then sliced into thin horizontal layers, which the 3D printer uses as a blueprint to construct the object. Various methods exist within 3D printing, each with distinct advantages:

- Fused Deposition Modeling (FDM): This is one of the most common methods, where a thermoplastic filament is heated and extruded through a nozzle, layer by layer.

- Stereolithography (SLA): Utilizes a laser to cure liquid resin into hardened plastic in a layer-by-layer fashion.

- Selective Laser Sintering (SLS): Involves a laser that fuses powdered material, which can range from nylon to metals, to form a solid structure.

Each method has its own set of materials and applications, making 3D printing a versatile tool in the manufacturing arsenal. The choice of technique often depends on the desired properties of the final product, such as strength, flexibility, or transparency.

Applications Across Industries

The versatility of 3D printing allows it to be applied in diverse fields, each benefiting from its unique capabilities:

- Healthcare: 3D printing is revolutionizing healthcare by enabling the production of customized prosthetics, implants, and even bioprinted tissues. This personalization enhances patient outcomes and reduces recovery times.

- Aerospace: In aerospace, 3D printing is used to create lightweight yet strong components, reducing fuel consumption and increasing efficiency. The ability to produce complex geometries aids in the design of more aerodynamic parts.

- Automotive: The automotive industry leverages 3D printing for prototyping and producing parts on-demand, which reduces inventory costs and accelerates product development cycles.

These examples illustrate the profound impact 3D printing has across various sectors, providing solutions that were previously unattainable with traditional manufacturing techniques.

Benefits and Challenges of 3D Printing

3D printing offers numerous advantages that make it an attractive option for manufacturers:

- Customization: The ability to produce tailor-made products to meet specific needs is one of the most significant benefits of 3D printing.

- Reduced Waste: Unlike subtractive manufacturing, which cuts away material, 3D printing only uses the material necessary to create the object, minimizing waste.

- Rapid Prototyping: Designers can quickly produce prototypes to test form, fit, and function, speeding up the development process.

However, challenges remain in the widespread adoption of 3D printing. The high cost of equipment and materials can be prohibitive for small businesses. Additionally, the speed of production is slower compared to traditional methods, making it less suitable for mass production. Despite these challenges, ongoing advancements in technology and materials continue to enhance the capabilities and accessibility of 3D printing.

The Future of 3D Printing

As 3D printing technology continues to evolve, its future appears promising. Innovations in materials, such as bio-inks for tissue engineering and stronger composites for industrial applications, are expanding the possibilities of what can be printed. Additionally, advancements in speed and precision are making 3D printing more viable for large-scale production.

Future trends in 3D printing include:

- Mass Customization: The ability to produce customized products on a large scale will revolutionize consumer goods, allowing for personalized items at affordable prices.

- Decentralized Manufacturing: 3D printing enables local production, reducing the need for global supply chains and minimizing environmental impact.

- Sustainability: Continued development of eco-friendly materials and processes will make 3D printing a more sustainable option for manufacturing.

As these trends unfold, 3D printing is set to play an increasingly important role in the future of manufacturing, offering innovative solutions to meet the demands of a rapidly changing world.